Most homeowners start researching Spray foam insulation in Fort Worth, TX, for one reason: comfort. Hot upstairs, cold floors, “Why is this one room always worse?” and an HVAC system that never seems to shut off. Spray foam can help, but only when it’s applied in the right place, at the right thickness, with the right process.

This guide covers what spray foam is, how it works, and what to look for when hiring Lone Star Insulation.

What Is Spray Foam Insulation?

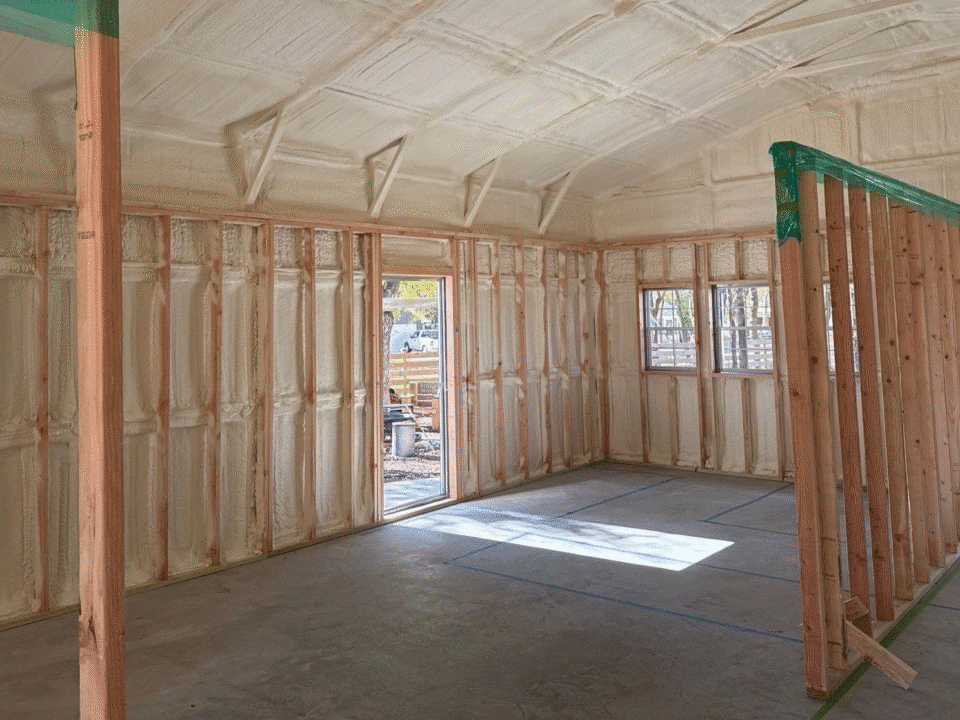

Spray polyurethane foam (SPF) is a spray-applied cellular plastic created by mixing chemicals that react and expand on contact, forming foam. Think of it as insulation that “grows” into the space instead of being cut and placed.

Common mistake: People assume spray foam is only about R-value. In real homes, the bigger win is often air control, stopping uncontrolled outside air from moving through small gaps in the building envelope.

Quick check: If you can feel drafts around attic access, recessed lights (when safe), plumbing penetrations, or along baseboards on a windy day, air leakage is part of the problem, so the insulation approach should address that, not just add depth.

How Does Spray Foam Insulation Work Once It’s Sprayed?

Two things happen fast:

- The chemicals mix and react, expanding into a foam.

- The foam adheres and hardens, creating a continuous layer across the surface.

That “continuous layer” is why spray foam often performs differently than batts or loose-fill: it can bridge irregular shapes, corners, and penetrations.

Proof-of-human detail: The “misses” aren’t usually in the middle of a big flat bay; they’re at transitions: top plates, rim joists, around pipes, and where framing gets weird. A good crew knows that and plans for it.

What’s The Difference Between Open-Cell And Closed-Cell Spray Foam?

Open-cell and closed-cell are different densities and behave differently. There is typical R-value-per-inch ranges: open-cell is commonly R-3.6 to R-4.5 per inch, and closed-cell is higher because it traps a blowing agent gas in closed cells.

Simple table: open-cell vs closed-cell

| Factor | Open-cell SPF | Closed-cell SPF |

| Typical R-value per inch | ~R-3.6 to R-4.5 | Higher R/inch (varies by product) |

| Density/feel | Softer, more “spongy.” | Denser, rigid |

| Common fit | Many interior cavities and some roofline assemblies (by design) | Rim joists, crawl spaces, areas needing more R/inch |

| Decision rule | If you need air sealing with more flexibility in drying, ask about open-cell | If you need higher R/inch and more rigidity, ask about closed-cell |

Common mistake: Choosing one type everywhere because “it’s better.” The right choice depends on location, moisture strategy, and thickness targets.

Where Does Spray Foam Make The Biggest Difference In A Fort Worth Home?

1) Attics with major air leakage

If your attic is part of the problem, the sequence matters. ENERGY STAR recommends sealing attic air leaks before adding insulation because it’s easier to seal first and get full performance.

2) Rim joists and band boards

These areas are classic leakage points and often benefit from a continuous foam layer.

3) Crawl spaces

When crawl spaces are drafty or damp, you need a plan that accounts for air movement, not just insulation depth.

Local factor: North Texas heat loads amplify small leaks. If your ductwork is in the attic (common in the region), air leakage and attic heat can stack, so insulation choices and duct sealing often go together.

What Should A “Done Right” Spray Foam Job Include?

If you’re pricing spray foam insulation in Fort Worth, TX, ask for this sequence in writing.

1) Assessment

Identify the thermal boundary (attic floor vs roofline), leakage points, and problem rooms.

2) Prep

Protect floors, storage, and mechanicals; plan access and lighting.

3) Air sealing plan (before “more insulation”)

Seal major bypasses first. ENERGY STAR emphasizes seal-first for attic projects.

4) Application

Apply foam in controlled passes; focus on transitions and penetrations, not just “big areas.”

5)Ventilation and isolation

EPA’s SPF ventilation guidance outlines key principles: establish airflow across the spraying area, isolate/contain the work zone, exhaust to a safe location, and ensure ventilation following application.

6)Verification

Photos, thickness checks, and a walkthrough before cleanup.

Realistic timeline driver: Prep and access. Tight attic entries or lots of stored items slow down safe, clean work (and that’s normal).

How Do You Choose An Insulation Contractor In Fort Worth?

Use a short interview script. It works whether you’re talking to Lone Star Insulation or any other insulation Contractor in Fort Worth that homeowners consider.

Ask:

- “Which foam type are you recommending, and where exactly will it be applied?”

- “What thickness targets are included in the scope (by area)?”

- “What’s your ventilation and re-occupancy plan?”

- “How will you verify coverage and thickness before you leave?”

- “Can you show {LICENSES_CERTS}, {YEARS}, {WARRANTY}, and {PROCESS} in writing?”

If you’re looking specifically for a spray foam insulation company in Fort Worth residents trust, you’re really looking for process clarity: scope, safety, verification, and no vague “we’ll take care of it.”

Conclusion

Spray foam works because it expands into place, adheres, and can create a continuous insulating and air-sealing layer when installed correctly. If you’re evaluating Spray foam insulation in Fort Worth, TX, Lone Star Insulation can walk you through the right foam type, the right locations, and a clean process, then verify the work so you’re not guessing.

FAQs

Is spray foam insulation different from traditional insulation?

Yes. Traditional insulation (fiberglass batts or blown-in) mainly slows heat flow; spray foam can also reduce air movement when installed continuously.

How long does spray foam take to install?

Timelines depend on access, prep, and scope. Attics with easy access are faster; tight entries and lots of penetrations add time.

Do I need ventilation during installation?

Yes. EPA guidance describes ventilation and containment principles during SPF application and ventilation after application.

Is open-cell or closed-cell “better”?

Neither is automatically better. Open-cell has typical R-values around R-3.6 to R-4.5 per inch; closed-cell is higher R per inch and denser.

Can spray foam be used with attic insulation or blown-in insulation?

Often, yes. Many projects use foam for air sealing at key leaks and blown-in for cost-effective depth afterward (depending on design and scope).

Do I need to remove old insulation first?

Not always. Removal is typically for contamination, moisture issues, or when it blocks air sealing and repair work.

What should I receive after the job?

A walkthrough, photos, and confirmation of thickness/coverage, plus your warranty details.

What’s the fastest way to compare bids?

Compare scopes, not totals: foam type, thickness targets, ventilation plan, and verification steps.