Your metal shop or warehouse feels like an oven during Texas summers, and your energy bills keep climbing higher each month. Spray foam insulation for warehouses in Texas can cut cooling costs by up to 50% while creating a more comfortable work environment year-round.

This guide breaks down the pros and cons of spray foam for commercial buildings, compares different foam types, and shows you what to expect for installation costs.

You might be surprised by how much money you’re losing right now.

Advantages of Using Spray Foam in Shops and Warehouses

Spray foam brings serious advantages to Texas shops and warehouses, where brutal summers can turn your workspace into an oven. You’ll see dramatic improvements in energy costs, comfort levels, and moisture control that make this investment pay for itself over time.

Improved energy efficiency

Your energy bills can drop significantly with spray foam insulation for metal buildings in Texas. Air leaks cost you money every month by forcing your HVAC system to work overtime. Closed-cell spray foam commercial Texas applications create an airtight seal that stops conditioned air from escaping through gaps, cracks, and seams in your building envelope.

Commercial buildings lose up to 40% of their energy through poor insulation and air leakage. Spray foam tackles both problems at once by expanding into every nook and cranny. Your heating and cooling costs decrease because the system doesn’t have to fight against drafts and temperature swings.

The Lone Star Insulation team has seen warehouse owners cut their energy bills by 30-50% after proper spray foam installation using our building-science-first approach.

Enhanced insulation and temperature control

Energy savings go hand in hand with better temperature control throughout your facility. Spray foam creates an airtight barrier that stops hot Texas air from sneaking into your warehouse during those scorching summer months.

This tight seal prevents your cooling system from working overtime to battle outdoor heat infiltration.

Commercial spray foam insulation cost in Texas may seem steep upfront, but the temperature stability pays dividends. Our team at Lone Star Insulation has witnessed warehouses drop their energy bills by significant amounts after proper spray foam installation.

The foam eliminates those frustrating hot spots that make workers miserable and damage inventory. Cold winter air stays outside where it belongs, while conditioned air stays put inside your building.

Condensation control spray foam Texas applications work especially well in metal buildings that typically sweat like a cold drink on a hot day.

Types of Spray Foam Suitable for Shops and Warehouses

You have two main spray foam options for your Texas shop or warehouse, and each works differently for your building. Closed-cell foam acts like a tough barrier that blocks air and moisture, while open-cell foam focuses more on sound control and costs less upfront.

Closed-cell spray foam

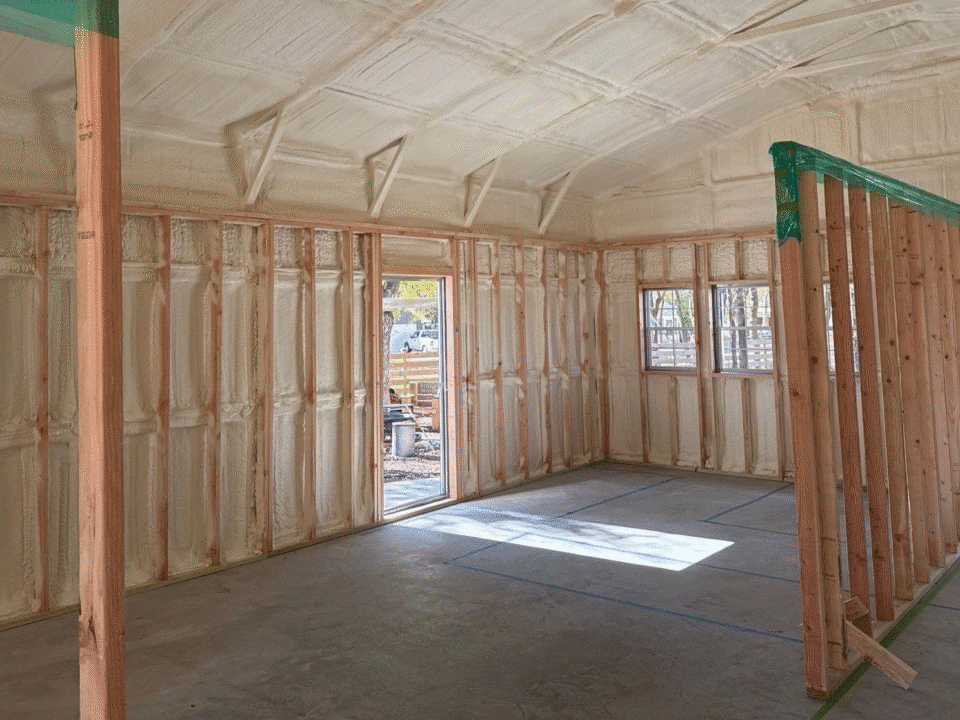

Closed-cell spray foam creates an airtight barrier that stops hot Texas air from sneaking into your shop or warehouse. This dense foam expands to fill every crack and gap, making your building envelope rock-solid.

We’ve seen firsthand how this material transforms sweltering warehouses into comfortable work spaces, even during those brutal Texas summers when your warehouse gets too hot. The foam’s rigid structure provides both insulation and structural support to metal buildings.

Lone Star Insulation specializes in closed-cell applications for both new construction and retrofit projects across the DFW area. Our building-science-first approach focuses on identifying air leakage paths that make your warehouse too hot in the summer in Texas conditions.

This foam delivers superior performance compared to traditional insulation methods, creating a continuous thermal barrier that keeps conditioned air where it belongs. Open-cell spray foam offers different benefits for specific applications.

Open-cell spray foam

Open-cell spray foam works like a sponge, expanding to fill gaps and cracks in your shop or warehouse walls. This type of insulation creates an effective air barrier while allowing moisture to pass through.

You’ll find it costs less than closed-cell options, making it a smart choice for large commercial spaces. The foam expands up to 100 times its original size, sealing those hard-to-reach areas where air leaks love to hide.

Texas weather throws curveballs with scorching summers and surprise cold snaps, but this foam handles both extremes well. The material seals air leaks that drive up energy bills, helping your HVAC system work smarter, not harder.

Commercial property owners see real improvements in building performance after installation.

Key Considerations for Installing Spray Foam in Texas

Installing spray foam in Texas shops and warehouses requires careful planning to match our state’s demanding climate conditions. You’ll want to consider factors like humidity levels, temperature swings, and local building codes before making your final decision.

Climate adaptability

Texas throws everything at your building, from scorching 105-degree summers to surprise freezing spells that catch folks off guard. Your warehouse needs insulation that rolls with these punches.

Spray foam adapts to extreme temperature swings better than traditional materials because it expands and contracts without losing its seal. Our building-science-first approach analyzes how air moves through your space during these wild weather changes.

This analysis helps us apply spray foam that maintains its performance whether you’re dealing with August heat or a February freeze.

Commercial spaces face unique challenges in Texas’s climate. Spray foam creates an air barrier that stops hot, humid air from sneaking into your cooled warehouse during the summer months.

Cold snaps can’t penetrate this barrier either, keeping your indoor temperature stable year-round. Over 50 years of combined jobsite experience has shown us how spray foam holds up against Texas weather extremes.

The material’s flexibility prevents cracks that develop in rigid insulation systems during temperature changes. Cost-effectiveness becomes the next major factor to consider for your warehouse project.

Cost-effectiveness

Spray foam insulation pays for itself faster than you might think in Texas commercial buildings. Your energy bills drop significantly during those scorching summer months and chilly winter nights.

Most shop and warehouse owners see their investment return within three to five years through reduced HVAC costs. The material lasts decades without needing replacement, unlike traditional insulation that sags and loses effectiveness over time.

Installation costs vary based on your building size and foam type selection. Closed-cell foam costs more upfront but delivers superior performance in extreme weather conditions. Open-cell options provide solid value for smaller budgets while still boosting energy efficiency.

Factor in potential tax incentives and utility rebates available for commercial energy improvements, and the numbers look even more attractive.

Conclusion

Spray foam proves itself as a smart choice for Texas shops and warehouses. Your building will stay cooler in summer and warmer during those surprise winter cold snaps. Energy bills drop significantly when you seal air leaks properly.

At Lone Star Insulation, we’ve seen countless commercial properties transform their comfort and efficiency with professional spray foam installation. Contact us today to discuss how spray foam can work for your specific facility needs.

FAQs

1. Does spray foam insulation work well in Texas heat?

Yes, spray foam acts like a superhero cape for your building, blocking that brutal Texas sun from turning your warehouse into an oven. It keeps the cool air in and the scorching heat out, which means your AC won’t work overtime.

2. Will spray foam save money on energy bills for large buildings?

You bet it will. Think of spray foam as plugging every tiny hole where your money usually flies out the window. Most shop owners see their energy costs drop by 30 to 50 percent after installation.

3. Can spray foam handle Texas humidity in warehouses?

Spray foam laughs in the face of humidity. It creates an airtight seal that stops moisture from sneaking into your building, preventing mold and keeping your inventory safe and dry.

4. Is spray foam insulation worth the upfront cost for commercial buildings?

Here’s the deal: spray foam costs more initially, but it pays for itself faster than you can say “yeehaw.” Between energy savings, fewer repairs, and better comfort for workers, most businesses break even within three to five years.