Are you tired of high energy bills, drafty rooms, and uncomfortable temperatures throughout your home? Understanding how spray foam insulation works: a simple guide for homeowners can help you discover a solution that addresses these common problems while providing long-term value. This comprehensive guide breaks down the science, benefits, and installation process of spray foam insulation in terms that every homeowner can understand.

What is Spray Foam Insulation?

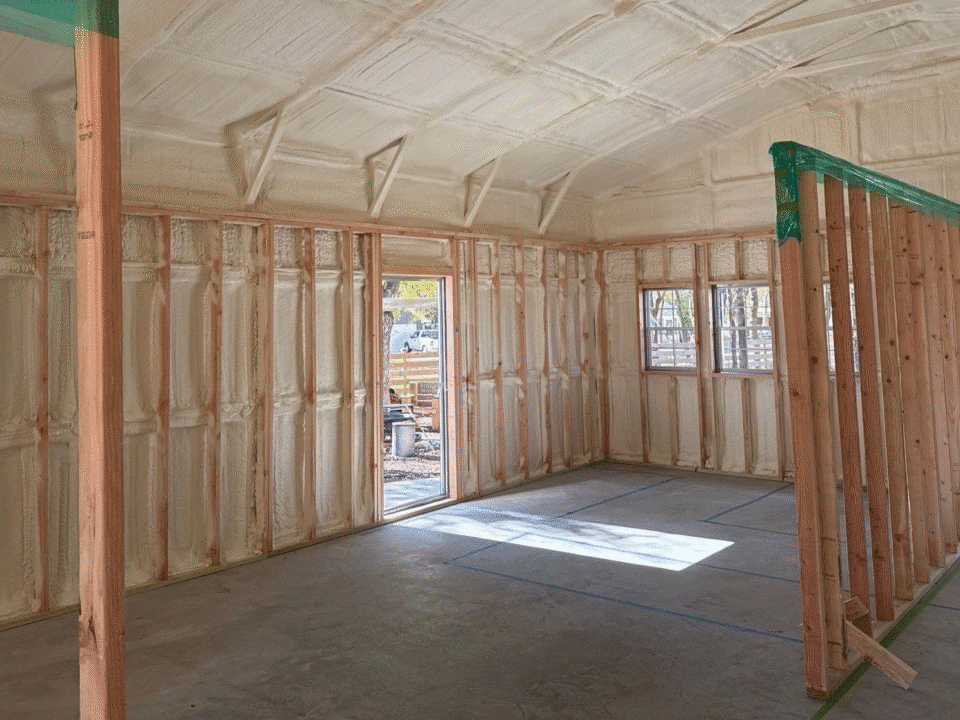

Spray foam insulation is a two-part liquid mixture that combines polyol resin and isocyanate to create an expanding foam when applied. Think of it as a liquid that transforms into a solid barrier, filling every crack, gap, and crevice in your home’s structure. Unlike traditional insulation materials like fiberglass batts that simply sit between wall studs, spray foam actively seeks out and seals air leaks while providing superior thermal resistance.

There are two main types of spray foam insulation:

- Open-Cell Spray Foam: This lighter, less dense option has an R-value of approximately 3.5 per inch. It’s softer and more flexible, making it ideal for interior walls and sound-dampening applications.

- Closed-Cell Spray Foam: This denser, more rigid foam offers an R-value of about 6.5 per inch. It provides structural strength and acts as both an air and moisture barrier, making it perfect for exterior walls, basements, and crawl spaces.

The Science Behind Spray Foam: How It Actually Works

The magic of spray foam lies in its chemical reaction and expansion process. When the two liquid components mix during application, they undergo an immediate chemical reaction that causes the mixture to expand up to 30-100 times its original volume within seconds.

Here’s how the process unfolds:

- Mixing and Application: Professional installers use specialized equipment to combine the two chemicals at the spray gun tip, ensuring proper ratios for optimal performance.

- Rapid Expansion: The mixture expands quickly, filling every available space, including tiny cracks and gaps that other insulation materials can’t reach.

- Adhesion and Curing: The foam adheres to all surfaces it touches, creating an airtight seal. Within hours, it cures into a solid, stable insulation barrier.

- Air Sealing Properties: Unlike traditional insulation that only provides thermal resistance, spray foam creates a complete air barrier, eliminating drafts and air infiltration that can account for up to 40% of energy loss in homes.

How Does Spray Foam Insulation Reduce Energy Bills?

The primary way spray foam works to save money is through its exceptional air sealing capabilities combined with high thermal resistance. Traditional insulation materials like fiberglass allow air to pass through, creating convective heat transfer that reduces effectiveness. Spray foam eliminates this problem by creating a continuous barrier.

Energy Efficiency Benefits:

- Reduces heating and cooling costs by 30-50% compared to traditional insulation

- Eliminates thermal bridging through framing members

- Prevents stack effect air movement that causes energy loss

- Improves HVAC system efficiency by reducing workload

Comfort and Indoor Air Quality Improvements

Beyond energy savings, spray foam insulation significantly improves home comfort and indoor air quality. The airtight seal prevents outdoor pollutants, allergens, and moisture from entering your living space. This creates a healthier indoor environment and helps maintain consistent temperatures throughout your home.

Additional Comfort Benefits:

- Eliminates cold spots and drafts

- Reduces humidity fluctuations

- Provides excellent sound-dampening properties

- Prevents pest infiltration through small openings

The Installation Process: What Homeowners Should Expect

Understanding how spray foam insulation works includes knowing what happens during professional installation. This is not a DIY project due to safety requirements and specialized equipment needs.

Pre-Installation Preparation:

- Installers inspect the area and identify air leak locations

- Electrical and plumbing work must be completed first

- Protective coverings are placed over windows, fixtures, and belongings

- Proper ventilation is established for safety

Application Day:

- Professional crews arrive with specialized spray equipment

- The two-part mixture is applied in thin, even passes

- Foam expands to fill cavities completely

- Excess foam is trimmed after curing

- Curing time varies from 4-24 hours depending on conditions

Safety Considerations:

During application, installers wear protective equipment, and homeowners should vacate the premises. Once cured, spray foam is completely safe and non-toxic, but the installation process requires proper ventilation and protection.

Addressing Common Homeowner Concerns

Is spray foam insulation safe after installation?

Yes, once properly cured, spray foam is completely safe and emits no harmful chemicals. The safety concerns are only during installation.

How long does spray foam last?

Properly installed spray foam insulation can last 80-100 years without degrading, making it a lifetime investment.

What about environmental impact?

Modern spray foam formulations are more environmentally friendly than ever, with some manufacturers offering bio-based options that reduce petroleum content.

Cost versus return on investment?

While initial costs are higher than traditional insulation, the energy savings typically pay for the investment within 5-10 years, followed by decades of continued savings.

Spray Foam vs. Other Insulation Types

When comparing how spray foam insulation works against alternatives like fiberglass, cellulose, or rigid foam boards, several key differences emerge:

Spray Foam Advantages:

- Creates a complete air seal (other insulations don’t)

- Higher R-value per inch than fiberglass or cellulose

- Doesn’t settle or degrade over time

- Provides moisture barrier (closed-cell)

- Adds structural strength to buildings

When to Choose Spray Foam:

- Existing homes with air leakage problems

- Basements and crawl spaces are prone to moisture

- Irregular cavities that are difficult to insulate

- When maximum energy efficiency is the goal

- Sound control is important

Making the Right Decision for Your Home

Now that you understand how spray foam insulation works: a simple guide for homeowners has shown you the science, benefits, and installation process. The key is determining whether your home’s specific needs align with spray foam’s advantages.

Consider spray foam if you’re experiencing high energy bills, uncomfortable rooms, excessive dust, or moisture problems. The initial investment typically pays for itself through energy savings while providing comfort improvements that last a lifetime.

Ready to explore spray foam insulation for your home? Contact local certified installers like Lone Star Insulation for a professional assessment and quote. They can evaluate your specific situation and help determine if spray foam is the right solution for your insulation needs.