Most insulation problems aren’t “you need more inches.” They’re “your house is leaking air in the wrong places.” In North Texas, attic heat and windy days can expose every little gap: a hot upstairs, musty closets, and rooms that never match the thermostat. Spray foam is a strong tool, but only when it’s used with the right material, in the right location, and with the right safety steps during installation. This guide shows what to look for when hiring a spray foam insulation contractor in Weatherford, TX, what to verify after the job, and when air/duct sealing or insulation removal should happen first.

What Problems Does Spray Foam Solve In Homes Around Here?

Spray foam earns its reputation when air movement is the real enemy.

Quick homeowner checklist (two-minute test):

- You feel temperature swings when the HVAC cycles off

- One or two rooms are always hotter/colder than the rest

- You can smell attic/garage odors inside the house

- Dust shows up fast near supply vents

Common mistake: Chasing the wrong problem. People add insulation but skip the leaks. ENERGY STAR points out that the attic is one of the biggest opportunities for savings, and that air sealing in the attic helps stop major leaks and maintain comfort.

Decision rule: If you have comfort issues plus drafts, prioritize an “air leakage first” scope, then pick the insulation type.

Where Should Spray Foam Go First?

A good contractor won’t start with “we foam everything.” They’ll start with “Where is the building envelope failing?”

High-impact first areas:

- Attic bypasses and top plates: These leaks let hot attic air and moisture move into the home. ENERGY STAR’s DIY guidance stresses finding and sealing big attic leaks first.

- Rim/band areas (if accessible): Small gaps here can make floors feel cold and add drafts

- Problem walls or bonus rooms: Only after you know what’s happening with air leakage pathways

Local factor: Wind and attic heat punish weak connections. That’s why a smart spray foam insulation in Weatherford, TX bid often includes air sealing details (penetrations, chases, transitions), not just “spray this many square feet.”

Open-Cell Or Closed-Cell: Which One Fits Your Project?

Use this table to keep your conversations grounded. The “right” choice depends on goals, moisture risk, and where the foam is going.

| Foam type | Best use-cases | Strengths | Watch-outs / decision rule |

| Open-cell | Interior assemblies where moisture exposure is low | Expands to fill cavities; good air sealing | If your project needs higher R per inch or added moisture resistance, ask about alternatives. |

| Closed-cell | Areas needing a higher R per inch or added moisture resistance | Higher R per inch than open-cell; more rigid | Costs more; thickness control matters; discuss code/covering needs with your installer. |

Common mistake: Choosing foam type based on a sales pitch instead of the building’s conditions. Ask the contractor to explain why they recommend one type in that specific location, and what they’ll do to verify thickness and coverage.

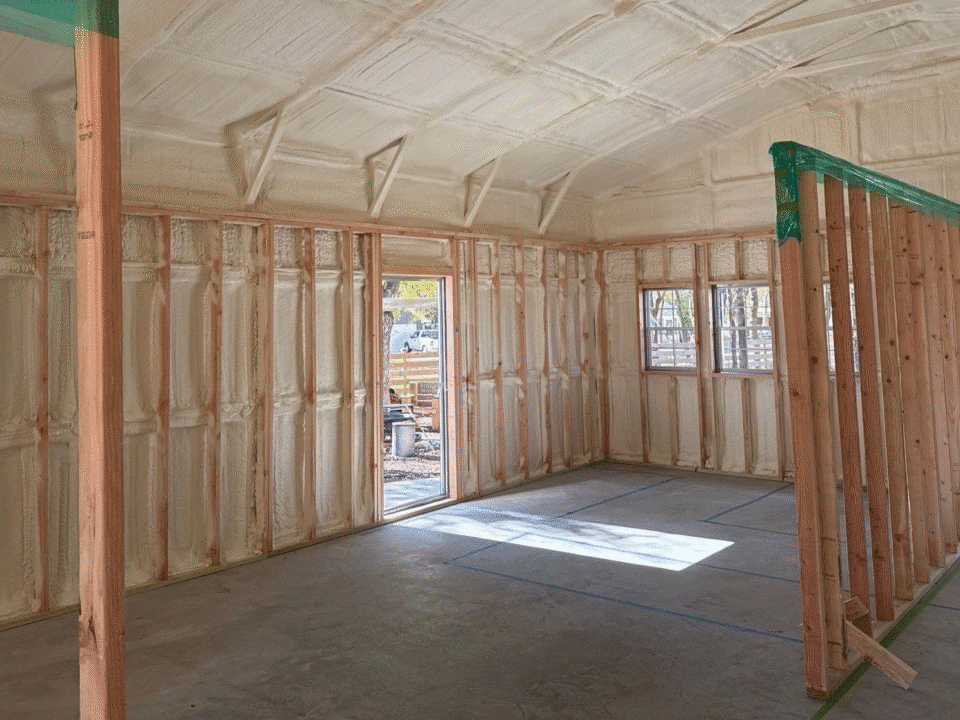

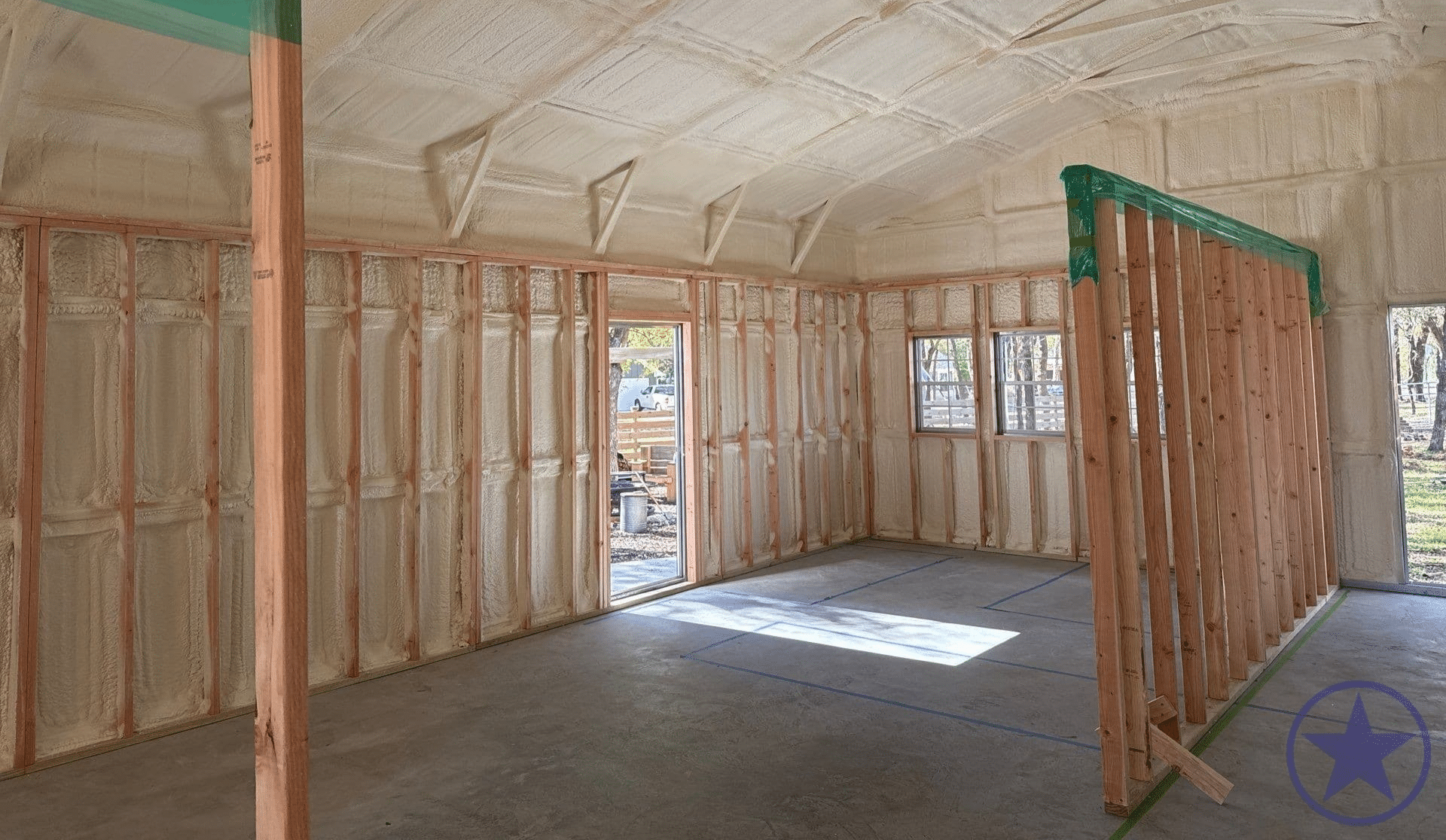

What Does A Quality Install Process Look Like From Start To Finish?

This is what you should expect from a professional crew doing spray foam insulation in Weatherford, TX, especially in an attic or wall application.

- Assessment and scope: They check access, existing insulation condition, signs of roof leaks, and major air leakage pathways.

- Plan the air sealing details: They identify penetrations and transitions that will be sealed before or during insulation work. ENERGY STAR’s guidance supports sealing major leaks as part of the job.

- Prep and protection: Mask off areas, protect HVAC equipment, and keep foam away from heat-sensitive fixtures.

- Ventilation and work-zone isolation (during spraying): EPA’s ventilation guidance describes establishing airflow across the spraying area and drawing vapors/mists away from workers, using exhaust to a safe location. For consumer safety expectations, the U.S. CPSC notes general industry guidance often suggests occupants stay out for about 24 hours, and that emissions can vary by foam type and conditions, so installers should follow manufacturer directions.

- Application (controlled lifts + depth checks): A quality crew applies foam in a controlled way and checks depth so you don’t end up with thin spots at corners and transitions.

- Verification walk-through: You should see what was insulated, what was sealed, and what wasn’t included.

Timeline reality: many residential scopes can be completed in a day or two, but prep, access, and removal can change that.

Should You Remove Old Insulation Or Seal Ducts Before Spray Foam?

This is where a lot of projects go sideways.

When insulation removal usually makes sense

- Old insulation is wet, contaminated, or blocking access to air leaks

- You need a clean substrate for certain applications

- You’re fixing odors/dust pathways from the attic

When duct sealing matters: If your ducts run through an attic, duct leakage can steal comfort even after insulation improves. Sealing major duct leaks is often part of an “air control” plan, especially when rooms are uneven.

Decision rule:

- If dust and comfort issues are tied to the attic, do air sealing + targeted removal first, then insulate.

- If airflow is weak in far rooms, consider duct sealing before assuming insulation alone will solve it.

What Drives The Cost And Timeline For Spray Foam Insulation Jobs?

Instead of guessing numbers, here are the real drivers:

- Access: tight attics and low-clearance areas take longer

- Prep/protection: finished homes need careful masking and containment

- Foam type and thickness: closed-cell generally costs more and may require more precise application

- Removal needs: removing old insulation adds labor, but can improve results

- Safety controls: ventilation setup and re-entry guidance are part of a professional job

Common mistake: comparing bids that don’t match the scope. A cheap quote often skips prep, sealing details, or verification.

Conclusion

Spray foam isn’t magic; it’s building science done well. When the job starts with air leaks, moisture risk, and a clear plan for ventilation and verification, the result is a home that’s easier to heat and cool and feels more consistent day to day. If you’re researching Spray foam insulation in Weatherford, TX, compare contractors by process: assessment, air sealing details, clean prep, controlled installation, and a final walk-through that proves what was done.

When you’re ready to plan the right scope, spray foam, attic and wall insulation, insulation removal, and air/duct sealing, contact Lone Star Insulation, LLC.

FAQs

Is spray foam really an air seal?

It can act as an air barrier when installed correctly, but the results depend on coverage and continuity. ENERGY STAR emphasizes sealing major leaks as part of attic performance improvements.

How long do we need to stay out after spray foam?

Re-entry guidance depends on the product and conditions. CPSC notes that general industry guidance often suggests 24 hours and recommends following the manufacturer’s instructions.

Open-cell or closed-cell in an attic?

Either can be used in the right scenario. The right choice depends on moisture risk, desired R-value per inch, and how the attic is being treated (vented vs unvented). Your installer should explain the reasoning clearly.

Can you spray foam over existing insulation?

Sometimes, but it can block access to air leaks and hide moisture issues. Many successful upgrades start with sealing big leaks and addressing contaminated insulation first.

Will spray foam lower my energy bills?

It can reduce energy waste when it improves air sealing and insulation quality, but results vary by home and existing leakage. ENERGY STAR highlights attic air sealing as a key step tied to energy savings potential.

Should I seal ducts before insulating?

If ducts are in a hot attic and you have uneven rooms, sealing major duct leaks can be a high-impact step. Insulation and duct sealing often work best together.

How do I vet a contractor quickly?

Ask for their step-by-step process, how they handle ventilation, how they verify thickness/coverage, and what their re-entry guidance is (based on the product being used).