If you’re building new and you want a tighter, more comfortable home from day one, spray foam is often the most practical path because it insulates and air-seals in the same step. That matters in a new build where small gaps become permanent drafts once drywall goes up.

For anyone searching for an insulation contractor in Weatherford, the main advantage of spray foam in new construction isn’t a magic material; it’s control: fewer air leaks, fewer weak spots, and fewer “why is this room always different?” surprises.

Why Does New Construction End Up Drafty Without The Right Insulation Plan?

Common mistake: Focusing on R-value while ignoring air movement. You can hit a high nominal R-value and still feel drafts if air is moving through gaps and around insulation.

Quick 60-second test you can do before drywall: Stand near an exterior wall and look for daylight at corners, pipe penetrations, or framing transitions. If you can see light, air can move.

Local factor: North Texas builds have to handle long cooling seasons and sudden cold snaps. That swing makes air leaks feel worse because the HVAC runs harder and longer to keep up.

Decision rule: If you want “even rooms,” treat air sealing as part of insulation, not an optional add-on.

What Makes Spray Foam A Strong Choice During New Construction?

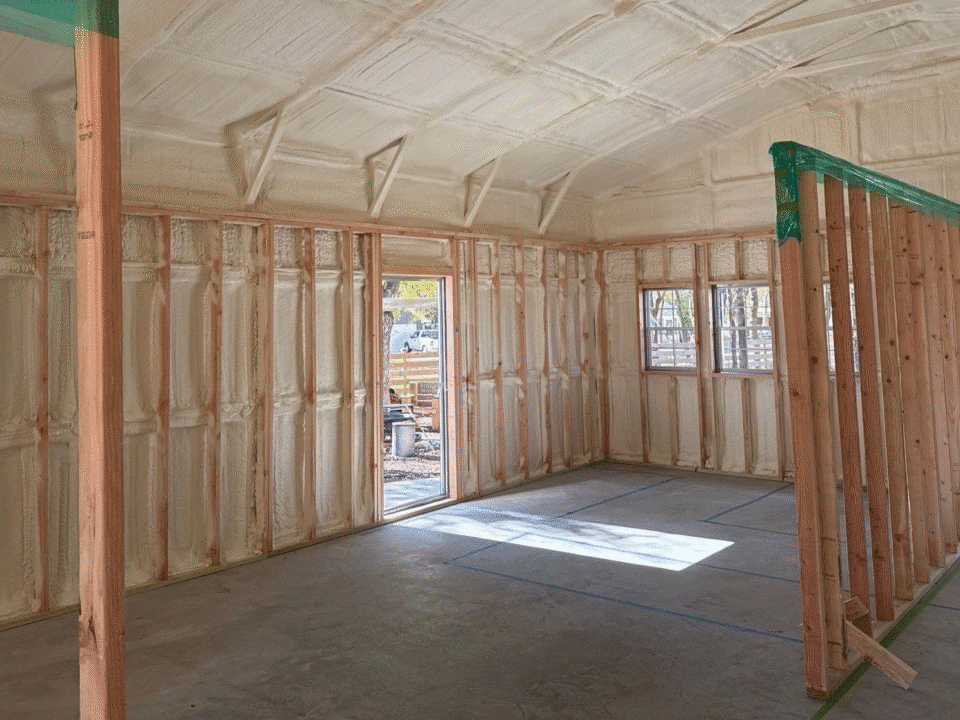

Spray foam insulation in Weatherford fits new construction because it matches the timeline and the access. Once drywall is up, the best air-sealing opportunities are gone.

Timeline driver: Installing foam while framing is still open often reduces the back-and-forth of “seal here, re-inspect, patch there,” because insulation and sealing happen together in the cavities and roofline.

Another practical advantage: Foam adheres to surfaces, so it doesn’t slump or fall out of place when installed correctly. That’s important in high-heat attic environments where loose or poorly supported materials can shift over time.

If you’re deciding whether it’s “worth it,” compare it to the cost of fixing comfort issues later. The easiest fixes are the ones you do before the house is finished.

Open-Cell Or Closed-Cell: How Do You Choose The Right Foam For Each Area?

Common mistake: Picking foam type based only on price per square foot.

A simple decision rule:

- If you need more R-value in less space or you’re insulating areas where moisture control is a bigger concern, closed-cell is often selected for targeted applications.

- If you’re insulating larger areas where flexibility and sound dampening can matter, open-cell is commonly used in residential assemblies.

What matters more than the label: the assembly and the details. A perfectly chosen foam still underperforms if the installer misses transitions, top plates, rim areas, and chases.

Quick checklist for your scope meeting:

- Where is the thermal boundary (roofline vs ceiling plane)?

- Where are the big penetrations (plumbing stacks, bath fans, recessed fixtures)?

- Are there ducts in the attic, and will they be sealed before insulation?

Should You Insulate The Attic Roofline Or The Ceiling In A New Build?

This is where new construction choices have long-term consequences.

Decision rule:

- If HVAC equipment or ducts will be in the attic, roofline insulation often helps because it brings that space closer to the conditioned envelope.

- If the attic will remain vented and unconditioned, a sealed ceiling plane can work if air sealing is done thoroughly before insulation.

Cost driver: Roofline foam can be a bigger upfront number, but it can also reduce future comfort complaints tied to hot attic conditions and duct losses. The right answer depends on your mechanical design and how the attic will be used.

Quick “builder sanity check”: If the plan is a vented attic with ceiling insulation, make sure the bid explicitly includes air sealing at top plates and penetrations. Vague language like “seal as needed” is where gaps survive.

How Do Spray Foam, Fiberglass & Blown-In Compare For New Construction?

Use this table to compare materials the way a builder does, by what they do and what they don’t.

| Option | Air sealing built-in? | Best fit in new construction | Watch-outs to plan for |

| Spray foam | Yes | Complex cavities, rooflines, and key leak areas | Needs correct thickness, clean surfaces, and proper ventilation during installation |

| Fiberglass batts | No | Straightforward wall cavities | Performance drops with gaps, compression, and missed air sealing |

| Blown-in (attic floor) | No | Flat ceiling planes after air sealing | Needs a tight ceiling plane first; wind washing and bypasses can hurt results |

If two bids are far apart, it’s usually scope. One includes air sealing and verification; the other assumes someone else will handle it.

What Does A Professional New-Construction Spray Foam Job Look Like Step-By-Step?

If you’re hiring an insulation contractor in Weatherford, a “done right” new construction job should read like a process, not a product.

- Assessment + plan: Confirm areas: attic/roofline, walls, rim/band areas, penetrations, and any duct plan.

- Pre-seal critical leaks (as needed): Some gaps get detailed before foam, especially around large chases and odd framing.

- Protect and prep: Mask windows, mechanicals, and areas that must stay clear for trades.

- Insulation installation: Apply foam to planned assemblies with consistent coverage at transitions.

- Ventilation during and after application: EPA guidance emphasizes ventilating the work zone during application to reduce exposure to mists and vapors. Follow product-specific guidance for re-entry/re-occupancy.

- Verification: Walkthrough photos, coverage checks at common miss areas (corners, top plates, chases), and, when part of the build plan, testing/inspection signoff.

What Mistakes Cause Spray Foam Problems Later?

Common failure modes:

- Insulating before the scope is finalized: If electricians and plumbers are still moving lines, you’ll end up with cut-outs and patches.

- Missed transitions: Most callbacks come from small, unsealed paths at framing changes, not from the big open areas.

- No ventilation plan: Spray foam installation should include ventilation steps during and after application, per EPA guidance, and re-occupancy timing should follow manufacturer direction.

- Treating ducts as “someone else’s problem”: Leaky ducts in a hot attic can undo a lot of good insulation.

Quick decision rule: If a spray foam insulation contractor in Weatherford can’t explain how they handle transitions and ventilation, don’t let them be the last trade before drywall.

Conclusion

Spray foam insulation in Weatherford can be the right move in new construction because it’s a practical way to lock in air sealing and insulation before finishes hide the evidence. The payoff shows up as fewer drafts, more even rooms, and fewer comfort fixes later.

If you’re looking for an insulation contractor in Weatherford for a new build, Lone Star Insulation can help you choose the right assembly, sequence the work correctly, and verify the installation before the house is closed in.

FAQs

Is spray foam always the right choice for every part of a new build?

Not always. Many homes use a hybrid approach, foam at key leak areas or the roofline, and other insulation elsewhere, based on design and budget.

Do I still need air sealing if I use spray foam?

Foam provides air sealing where it’s applied, but the plan still matters. The big leaks are often at transitions and penetrations, so those must be included in the scope.

Should ducts be sealed before insulation?

Yes, if ducts are in an unconditioned space, sealing major duct leaks before insulating is usually a high-impact step. It’s also easier to verify before everything is buried.

How long do I need to ventilate after spray foam?

EPA guidance focuses on ventilating during application and following product-specific guidance afterward; re-occupancy timing depends on the foam system and conditions.

What should I ask for in a new construction insulation quote?

Ask for exact areas being insulated, foam type, and target thickness by area, what air sealing is included, how they handle transitions, and what verification you’ll receive.

Can blown-in insulation still make sense in a new build?

Yes, especially on a flat ceiling plane, when the ceiling is air-sealed thoroughly first. DOE notes cellulose can be installed in different ways in new construction; the method should match the assembly.